Sawn sandstone paving and sawn granite paving can be further processed depending on how you want it. It can be:

- Smooth & Honed — when stone is completely sawn it is referred to as ‘six sides sawn’. After this process, the stone is lightly polished (honed) on the top surface to take out any of the saw marks and left with a matt to light satin smooth surface which still provides some grip. Click here to view our smoothed and honed sandstone paving products.

- Shotblast — During this process the stone is peppered (shot) with small beads of steel at high speed. This technique lightens the stone and works to make all of the sawn paving slabs a very similar colour with more uniformity. Sawn Indian sandstone can be shotblast to mask the coloured ‘veins’ that are often naturally present in sedimentary rock. It also provides a fantastic contemporary textured finish. Click here to view our shotblasted sandstone paving products.

- Flamed — (for sawn granite slabs only) this process heats the sawn granite block paving causing the grains in the stone to change colour. This is known as a ‘flamed finish’. It’s ideal for damp or outdoor areas, or for bathrooms in particular as it lightly vitrifies the surface making it less porous. Click here to view our flamed sawn granite paving products.

Sawn paving: colours, styles & textures for everyone

We provide sawn Indian sandstone in a variety of colours, including tones of earthy browns, greys and the ever-popular beige sawn sandstone paving (such as Autumn Brown, Kandla Grey and Yellow Mint). In our collection, you will also find green, blue and grey tones, and sawn Rainbow Indian sandstone.

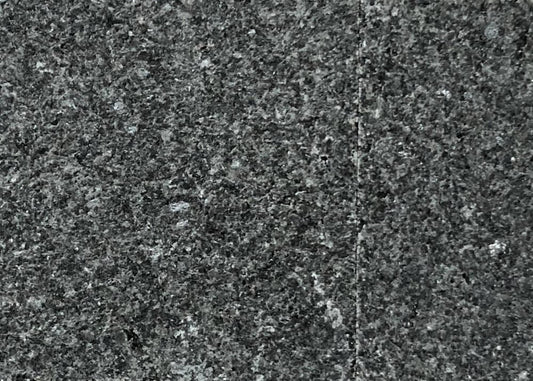

Our sawn granite ranges from silver, to blue-grey, to a more classic charcoal black. There are colours for everyone, and both sandstone and granite are ideal for inside or outside use.